Product details

9ZR-1.2 Type Straw Kneading Machine | |||

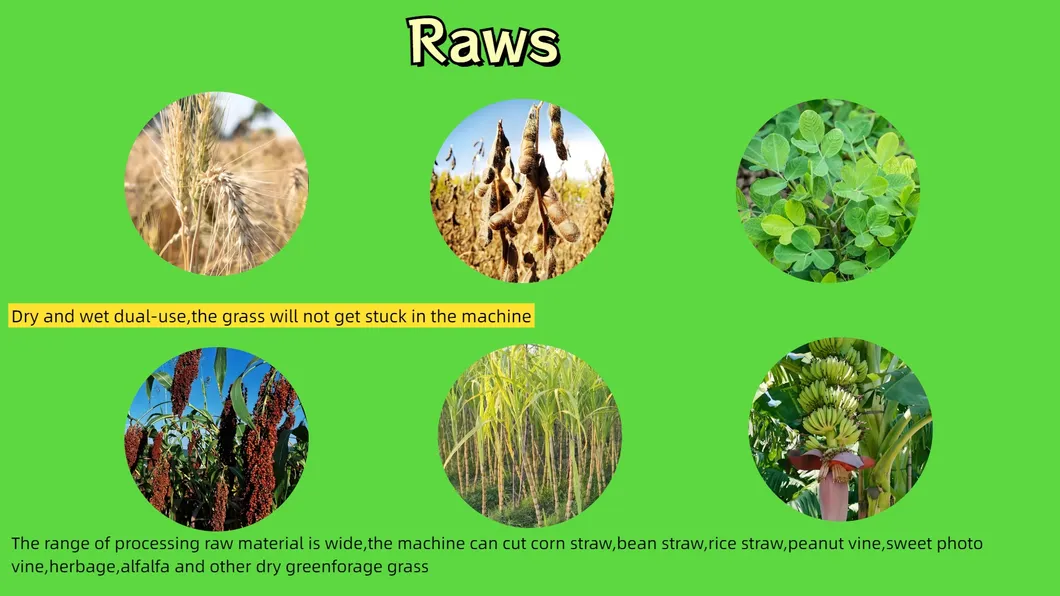

Supporting power: | 2.2-2.7kw | Applicable materials : | Straw, straw, straw, etc. |

Dimensions : | 1150x520x880mm | Applicable to : | Cattle , sheep , horses , deer , etc. |

Heavy Quantity : | 37kg | Applicable site : | Breeding factories , farmers , etc. |

Production Quantity : | 400 kg/h | Screen width: | 200mm |

Material Quality : | Steel plate | Number of moving knives: | 2 |

Spindle speed : | 4025r/min | Rotor diameter: | 290mm |

Hammer : | 20 tablets | Structure form: | Cutting and kneading type |

Product introduction

9ZR-1.2 straw kneading machine is a side-cutting and kneading high-efficiency equipment specially designed for livestock feed preparation, focusing on soft silk effect, energy-saving and portable Two big selling points. The combination of 20 hammers and 2 moving knives is adopted, the spindle speed reaches 4025r/min, and the dry straw processing capacity is 400kg/H, can knead straw, straw, straw and other raw materials into soft silk (more suitable for livestock chewing habits than traditional straw cutting); equipped with 2.2-2.7 kw power, energy saving and low consumption; Compact shape (1150 520 880 mm), weight is only 37 kg, and the pulley design is convenient to move, which is suitable for breeding plants, small and medium-sized farmers and other scenarios, and is a practical tool for straw resource utilization.

Use scenarios

- Large-scale material preparation of

- the breeding plant: the breeding plant uses it to treat corn stalks in the early morning, kneads the corn stalks as the basic feed for cattle, and the soft silk reduces the picky eating of cattle and improves the utilization rate of feed. Daily processing of

- small and medium-sized farmers: On weekends, farmers put their own straw and straw into the machine, knead them and then bag them for storage, so as to meet the feed needs of sheep and horses next week and reduce their dependence on finished feed. Resource utilization of straw after busy

- farming season: After busy farming season, farmers will knead the remaining wheat straw and corn straw into shreds instead of traditional burning methods, and convert them into livestock feed to realize straw Turn waste into treasure.

User value

- The palatability of the feed is

- improved: the softness of the kneaded straw is high, cattle, sheep, horses and other livestock are willing to take the initiative to eat, and the feed waste is reduced (about 15% -20% of the feed is saved compared with the straw cutting method).

- Improve the digestion efficiency: the silk is easy to chew and decompose, improve the digestion and absorption capacity of livestock to feed, and indirectly reduce the breeding cost.

- Energy saving and cost saving: low power consumption (2.2-2.7 kw), the cost of electricity per hour is about 1-2 yuan; high output ( 400 kg/H) reduces the time of material preparation and labor input. Convenient

- movement: 37 kg lightweight design, farmers can easily push to the courtyard, enclosure and other small sites to use, without additional handling equipment.

- Durable and economical: The steel plate is wear-resistant and corrosion-resistant, and the equipment has a long service life, reducing the cost of subsequent maintenance and replacement.

- Resource recycling: convert the straw that may have been burned into useful feed, reduce the cost of feed purchase (the cost of straw feed per catty is about 0.1-0.2 yuan, which is much lower than that of finished feed), and help environmental protection.

Application